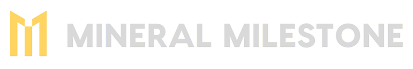

IMPACT IDLER-CONVEYOR IMPACT IDLER-133/390/25

R702,10

Impact idlers are specifically engineered to absorb shock and minimize damage at conveyor loading zones, where bulk material first makes contact with the belt. Their heavy‑duty rubber rings cushion the impact, reducing stress on both the belt and the supporting structure, ultimately extending equipment lifespan. By maintaining belt alignment and dissipating energy effectively, impact idlers improve overall system reliability and reduce maintenance downtime. They are an essential component in high‑impact areas across mining, aggregates, and material‑handling operations. Please note that the face length on impact rollers varies depending on the number of rubber discs. The gauge length remains in accordance with the SANS 1313 specification.

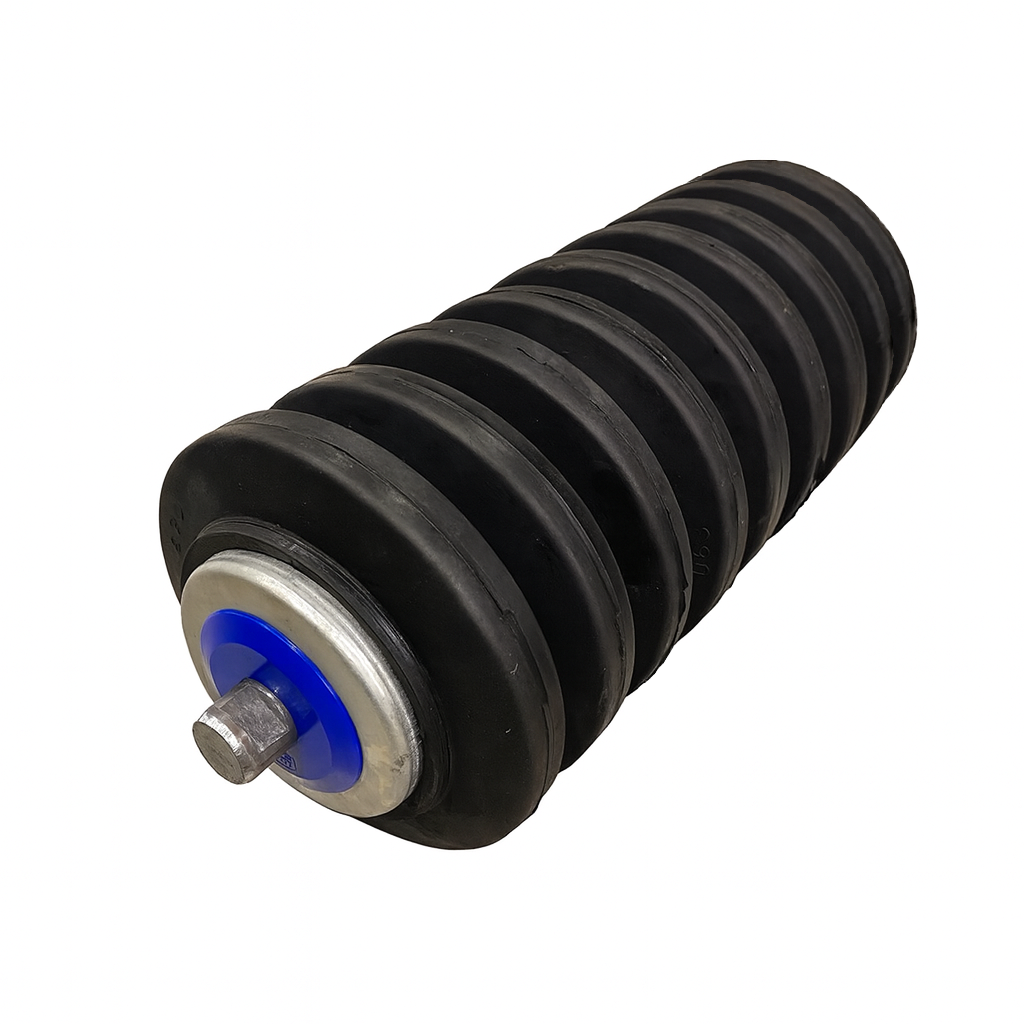

SPECIFICATIONS

IMPACT IDLER DIAMETER (D): 133

FACE LENGTH (FL): 390

SHELL WALL THICKNESS (WT): 4.5

SHAFT DIAMETER (SD): 25

SHAFT LENGTH (SL): 434

SHAFT SLOTTED WIDTH (CW): 12

SHAFT SLOT DIAMETER (CD): 18

PRODUCT TYPE: IMPACT IDLER

MATERIAL: Rubber SH60

BELT WIDTH (mm): 1050

STANDARDS: SANS 1313-SERIES 25

SHAFT MOUNTING: CLOSED END-SLOTTED

SHAFT MOUNTING CENTRE (MC): 412

BEARING TYPE: 6205 2RS C3 BEARINGS

BEARING FIX: EXTERNAL CIRCLIP

SEALS: 5 PART LAB SEALS

CAPS: DUST COVER (FLINGERS)

All dimensions are in mm.

OUR PRODUCTS

cOMMON pRODUCTS

R6,50

R8,40

R4 500,00

R1 100,00

R7,90

R4,90

R0,29

R11,90

R26,00

R24,10